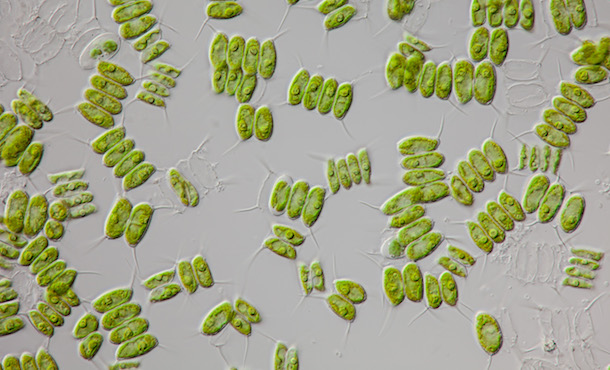

Microscopic image of Scenedesemus algae, one of the species showing potential for use as biofuel.

The future of energy: algae?

Penn State researchers part of team seeking to convert microalgae into clean-burning biofuel

3/28/2019

UNIVERSITY PARK, Pa. – Growing and cultivating microalgae as a source of cleaner-burning biofuel for compression ignition engines is the focus of a team of researchers from Penn State, the University of Delaware and the University of Michigan. The project is funded by a $2 million grant from the U.S. Department of Energy, and $500,000 of cost-share funding.

Aquatic microalgae grow quickly and can produce large amounts of biomass for use in production of biofuels without limitations present with land-based crop cultivation, such as needing large parcels of land and competition with food production. However, several challenges have prevented widespread adoption of biofuel produced with microalgae. These include low biomass return per unit energy, instability under commercial-scale field conditions, use of expensive fertilizers that can have adverse environmental impacts and lack of optimized chemical properties of the resulting fuel for combustion.

The researchers are hoping to design an optimized algal biofuel system. Instead of genetic engineering of algae to create a superior strain, the team is taking a more natural approach creating biofuel from algae.

“We're trying to use ecological engineering as opposed to genetic engineering,” Phillip Savage, Walter L. Robb Family Chair and department head of chemical engineering, said. “So instead of trying to make algae do something it doesn't naturally do, we want to work with algae in a polycultures, with lots of different species together.”

Having multiple species together living in the same pond enables adjustments to changing conditions. For example, if conditions such as temperature become less favorable for one species of algae, another species may thrive, or a scavenger enters the pond that eats one type but not any of the others.

This unique approach is being attempted by an interdisciplinary team of researchers, including Savage; an ecologist, Bradley Cardinale, professor in the School for Environment and Sustainability at Michigan; Andre Boehman, professor of mechanical engineering at Michigan; Dan Haworth, professor of mechanical engineering at Penn State; and Levi Thompson, dean of the University of Delaware’s College of Engineering.

The role that Savage’s lab plays in the research happens after the algae is harvested. His lab will perform a process on the algae called hydrothermal liquefaction, which converts the wet biomass into crude-like oil, also known as bio-oil. The process works via a combined action of thermal energy and pressure, and then water molecules attack some of the chemical bonds in the biomass. This breaks them down into smaller compounds that can be further processed into transportation fuels such as diesel.

Savage notes this is similar to how petroleum was produced from ancient organic material, but much faster.

“Petroleum formed as marine organisms and plants sunk to the bottom of these ancient seas and over time, the material accumulated and that generated pressure and then heat as it decayed, creating oil,” he said. “We're trying to do the same thing in a lab in a few minutes, instead of waiting geological time scales.”

Once Savage’s lab does the conversion of biocrude, the group at the University of Michigan will work on processing it to be more like a finished fuel. Then, Haworth and Boehman will model the chemistry and test the fuel in an internal combustion/compression ignition engine.

This entire process takes a new approach, one of close collaboration. Savage said that in the past one group would grow the algae, one group would work on the conversion and another group would work on combustion, but now all are working together.

“The idea is let’s get everyone around the table and understand all the issues,” Savage said. “When we see what happens when the fuel is being burned, that information is shared with the people who are refining it and the people who are growing the algae. We then will do some feedstock engineering and process engineering to give us a better fuel at the end.”

The overall goal is to create an optimized fuel that will burn cleaner and be more environmentally friendly. Part of the reduction of greenhouse gas emissions via this new fuel source is expected to come from the biofuel being a renewable resource.

If the team successfully produces a cleaner fuel, the next challenge is making the process scalable.

“There’s no reason why it can’t be scalable but ultimately it will come down to economics,” Savage said. “We will be able to come up with the technologies and I'm sure they'll work, it’s just a matter of whether they can work in a way that's competitive with fossil-derived diesel fuel.”